- Posts: 52

- Thank you received: 0

×

Donec eu elit in nisi placerat tincidunt in eu sapien. Proin odio nunc, interdum vel malesuada pretium, fringilla sit amet metus

Decoding Battery Chemistry: NMC vs LiFePO4 for Energy Storage

3 months 3 weeks ago #328385

by Margaret

In the world of energy storage, batteries play a crucial role, serving as the backbone for various applications ranging from portable electronics to electric vehicles and grid-scale energy storage systems. Among the myriad of battery chemistries available, two prominent contenders stand out: NMC (Nickel Manganese Cobalt) and LiFePO4 (Lithium Iron Phosphate). Both offer unique advantages and drawbacks, making them suitable for different use cases. In this comprehensive guide, we'll delve into the intricate details of NMC and LiFePO4 batteries, comparing their chemistry, performance characteristics, applications, and environmental impacts to help you decipher which option best suits your energy storage needs.

Understanding NMC Battery Chemistry

NMC batteries are a type of lithium-ion battery that utilizes a combination of nickel, manganese, and cobalt in varying ratios in the cathode. The anode typically consists of graphite. The composition of the cathode can vary, with common ratios being NMC 111 (equal parts nickel, manganese, and cobalt), NMC 532, and NMC 622, among others. Each ratio offers different trade-offs in terms of energy density, power density, cycle life, and cost.

NMC batteries are renowned for their high energy density, making them suitable for applications requiring long-duration energy storage, such as electric vehicles and renewable energy storage systems. Additionally, NMC batteries exhibit good overall performance, with high specific energy and good thermal stability. NMC vs LiFePO4 Battery

However, NMC batteries also come with some challenges. Cobalt, a key component in many NMC formulations, is relatively expensive and associated with ethical and environmental concerns due to mining practices. Moreover, NMC batteries have a lower inherent thermal stability compared to some other lithium-ion chemistries, requiring robust thermal management systems to ensure safety.

Exploring LiFePO4 Battery Chemistry

LiFePO4 batteries, on the other hand, utilize lithium iron phosphate as the cathode material, paired with graphite or another carbon-based material as the anode. Unlike NMC batteries, LiFePO4 batteries do not contain cobalt, which alleviates some of the ethical and environmental concerns associated with cobalt mining.

One of the standout features of LiFePO4 batteries is their exceptional cycle life. These batteries can endure a significantly higher number of charge-discharge cycles compared to NMC batteries, making them an ideal choice for applications that require frequent cycling, such as energy storage for solar power systems and uninterruptible power supplies (UPS).

Additionally, LiFePO4 batteries offer excellent thermal stability and safety characteristics. They are less prone to thermal runaway and have a lower risk of catching fire or exploding compared to some other lithium-ion chemistries, making them a preferred option for safety-critical applications.

However, LiFePO4 batteries typically have lower energy density compared to NMC batteries, resulting in larger and heavier battery packs for a given energy storage capacity. This limitation may make them less suitable for applications where space and weight are constraints, such as electric vehicles.

Comparing Performance Characteristics

When comparing the performance characteristics of NMC and LiFePO4 batteries, several factors come into play:

Energy Density: NMC batteries generally offer higher energy density compared to LiFePO4 batteries, providing greater energy storage capacity per unit weight or volume.

Power Density: NMC batteries often have higher power density, enabling rapid charging and discharging, which is advantageous for applications requiring high power output.

Cycle Life: LiFePO4 batteries excel in cycle life, capable of enduring thousands of charge-discharge cycles with minimal degradation, whereas NMC batteries typically have a shorter cycle life.

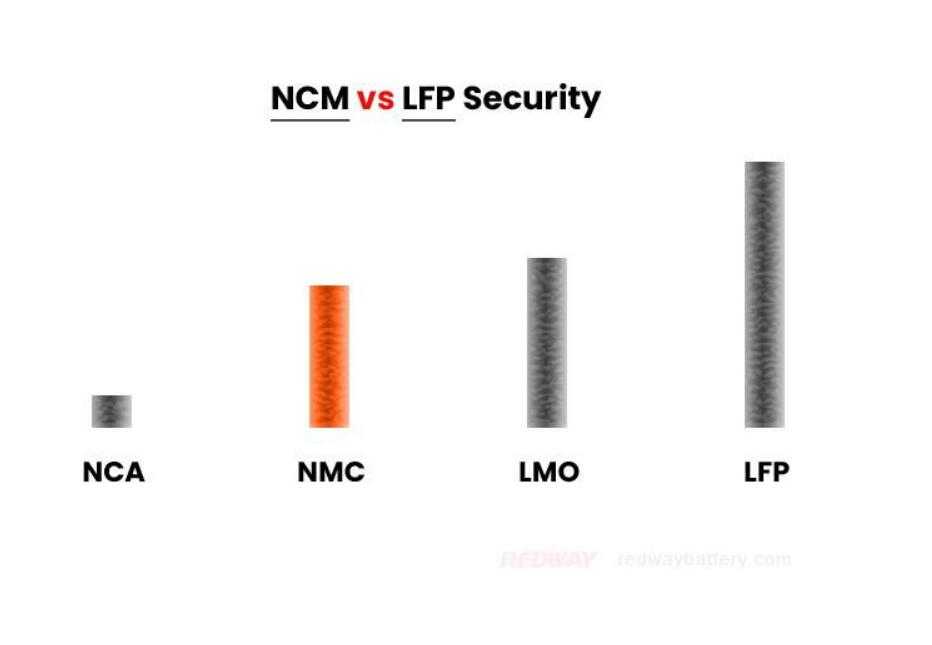

Safety: LiFePO4 batteries are considered safer than NMC batteries due to their inherently stable chemistry and reduced risk of thermal runaway.

Cost: The cost of NMC and LiFePO4 batteries can vary depending on factors such as raw material prices, manufacturing processes, and economies of scale.

Applications of NMC and LiFePO4 Batteries

Both NMC and LiFePO4 batteries find applications across various industries, each catering to specific requirements:

Electric Vehicles (EVs): NMC batteries are commonly used in electric vehicles due to their high energy density and power output, enabling longer driving ranges and faster acceleration. However, some EV manufacturers opt for LiFePO4 batteries for their superior safety and cycle life.

Renewable Energy Storage: Both NMC and LiFePO4 batteries are utilized for storing energy from renewable sources such as solar and wind power. NMC batteries are preferred for grid-scale applications where energy density and power output are critical, while LiFePO4 batteries are favored for residential and commercial installations requiring long-term reliability.

Consumer Electronics: NMC batteries dominate the consumer electronics market, powering smartphones, laptops, tablets, and other portable devices due to their high energy density and compact size.

Backup Power Systems: LiFePO4 batteries are commonly used in backup power systems, UPS units, and emergency lighting systems where reliability and long-term performance are paramount.

Environmental Considerations

In terms of environmental impact, both NMC and LiFePO4 batteries have their challenges. The mining and processing of raw materials for battery production, such as lithium, cobalt, nickel, and graphite, can have significant environmental consequences, including habitat destruction, water pollution, and carbon emissions. Additionally, the disposal and recycling of spent batteries present challenges in terms of resource recovery and waste management.

Efforts are underway to address these environmental concerns through improved mining practices, material recycling, and the development of alternative battery chemistries with lower environmental footprints.

Conclusion

In the realm of energy storage, the choice between NMC and LiFePO4 batteries depends on a multitude of factors, including application requirements, performance characteristics, safety considerations, and environmental impacts. While NMC batteries offer higher energy density and power output, LiFePO4 batteries excel in cycle life and safety. Selecting the optimal battery chemistry involves weighing these factors against specific application needs and sustainability goals.

Ultimately, whether you opt for NMC or LiFePO4 batteries, it's essential to prioritize safety, reliability, and environmental sustainability to ensure the long-term viability of energy storage solutions in an increasingly electrified world.

In summary, NMC and LiFePO4 batteries each have their strengths and weaknesses, and understanding their respective chemistries and performance characteristics is crucial for making informed decisions in energy storage applications.

By exploring the nuances of NMC vs LiFePO4 battery technologies, we can decipher the complexities of battery chemistry and pave the way for more sustainable and efficient energy storage solutions in the future.

In the world of energy storage, batteries play a crucial role, serving as the backbone for various applications ranging from portable electronics to electric vehicles and grid-scale energy storage systems. Among the myriad of battery chemistries available, two prominent contenders stand out: NMC (Nickel Manganese Cobalt) and LiFePO4 (Lithium Iron Phosphate). Both offer unique advantages and drawbacks, making them suitable for different use cases. In this comprehensive guide, we'll delve into the intricate details of NMC and LiFePO4 batteries, comparing their chemistry, performance characteristics, applications, and environmental impacts to help you decipher which option best suits your energy storage needs.

Understanding NMC Battery Chemistry

NMC batteries are a type of lithium-ion battery that utilizes a combination of nickel, manganese, and cobalt in varying ratios in the cathode. The anode typically consists of graphite. The composition of the cathode can vary, with common ratios being NMC 111 (equal parts nickel, manganese, and cobalt), NMC 532, and NMC 622, among others. Each ratio offers different trade-offs in terms of energy density, power density, cycle life, and cost.

NMC batteries are renowned for their high energy density, making them suitable for applications requiring long-duration energy storage, such as electric vehicles and renewable energy storage systems. Additionally, NMC batteries exhibit good overall performance, with high specific energy and good thermal stability. NMC vs LiFePO4 Battery

However, NMC batteries also come with some challenges. Cobalt, a key component in many NMC formulations, is relatively expensive and associated with ethical and environmental concerns due to mining practices. Moreover, NMC batteries have a lower inherent thermal stability compared to some other lithium-ion chemistries, requiring robust thermal management systems to ensure safety.

Exploring LiFePO4 Battery Chemistry

LiFePO4 batteries, on the other hand, utilize lithium iron phosphate as the cathode material, paired with graphite or another carbon-based material as the anode. Unlike NMC batteries, LiFePO4 batteries do not contain cobalt, which alleviates some of the ethical and environmental concerns associated with cobalt mining.

One of the standout features of LiFePO4 batteries is their exceptional cycle life. These batteries can endure a significantly higher number of charge-discharge cycles compared to NMC batteries, making them an ideal choice for applications that require frequent cycling, such as energy storage for solar power systems and uninterruptible power supplies (UPS).

Additionally, LiFePO4 batteries offer excellent thermal stability and safety characteristics. They are less prone to thermal runaway and have a lower risk of catching fire or exploding compared to some other lithium-ion chemistries, making them a preferred option for safety-critical applications.

However, LiFePO4 batteries typically have lower energy density compared to NMC batteries, resulting in larger and heavier battery packs for a given energy storage capacity. This limitation may make them less suitable for applications where space and weight are constraints, such as electric vehicles.

Comparing Performance Characteristics

When comparing the performance characteristics of NMC and LiFePO4 batteries, several factors come into play:

Energy Density: NMC batteries generally offer higher energy density compared to LiFePO4 batteries, providing greater energy storage capacity per unit weight or volume.

Power Density: NMC batteries often have higher power density, enabling rapid charging and discharging, which is advantageous for applications requiring high power output.

Cycle Life: LiFePO4 batteries excel in cycle life, capable of enduring thousands of charge-discharge cycles with minimal degradation, whereas NMC batteries typically have a shorter cycle life.

Safety: LiFePO4 batteries are considered safer than NMC batteries due to their inherently stable chemistry and reduced risk of thermal runaway.

Cost: The cost of NMC and LiFePO4 batteries can vary depending on factors such as raw material prices, manufacturing processes, and economies of scale.

Applications of NMC and LiFePO4 Batteries

Both NMC and LiFePO4 batteries find applications across various industries, each catering to specific requirements:

Electric Vehicles (EVs): NMC batteries are commonly used in electric vehicles due to their high energy density and power output, enabling longer driving ranges and faster acceleration. However, some EV manufacturers opt for LiFePO4 batteries for their superior safety and cycle life.

Renewable Energy Storage: Both NMC and LiFePO4 batteries are utilized for storing energy from renewable sources such as solar and wind power. NMC batteries are preferred for grid-scale applications where energy density and power output are critical, while LiFePO4 batteries are favored for residential and commercial installations requiring long-term reliability.

Consumer Electronics: NMC batteries dominate the consumer electronics market, powering smartphones, laptops, tablets, and other portable devices due to their high energy density and compact size.

Backup Power Systems: LiFePO4 batteries are commonly used in backup power systems, UPS units, and emergency lighting systems where reliability and long-term performance are paramount.

Environmental Considerations

In terms of environmental impact, both NMC and LiFePO4 batteries have their challenges. The mining and processing of raw materials for battery production, such as lithium, cobalt, nickel, and graphite, can have significant environmental consequences, including habitat destruction, water pollution, and carbon emissions. Additionally, the disposal and recycling of spent batteries present challenges in terms of resource recovery and waste management.

Efforts are underway to address these environmental concerns through improved mining practices, material recycling, and the development of alternative battery chemistries with lower environmental footprints.

Conclusion

In the realm of energy storage, the choice between NMC and LiFePO4 batteries depends on a multitude of factors, including application requirements, performance characteristics, safety considerations, and environmental impacts. While NMC batteries offer higher energy density and power output, LiFePO4 batteries excel in cycle life and safety. Selecting the optimal battery chemistry involves weighing these factors against specific application needs and sustainability goals.

Ultimately, whether you opt for NMC or LiFePO4 batteries, it's essential to prioritize safety, reliability, and environmental sustainability to ensure the long-term viability of energy storage solutions in an increasingly electrified world.

In summary, NMC and LiFePO4 batteries each have their strengths and weaknesses, and understanding their respective chemistries and performance characteristics is crucial for making informed decisions in energy storage applications.

By exploring the nuances of NMC vs LiFePO4 battery technologies, we can decipher the complexities of battery chemistry and pave the way for more sustainable and efficient energy storage solutions in the future.

Please Log in or Create an account to join the conversation.

Time to create page: 0.288 seconds